Types of Paracord

Paracord, aka parachute cord (also sometimes called “550 cord” or "550 paracord"), is a type of durable utility cordage that was developed by the U.S. Military during World War II for parachute suspension lines. It was basically the thin cordage connecting the soldier’s harness below, to the parachute canopy above. It was designed to be lightweight, strong, durable, and have a 30% stretch to absorb the shock that occurs when a parachute canopy deploys.

Because the paracord was so lightweight and useful, landing paratroopers would quickly cut away most of the suspensions lines, store it in their packs, and then use it for utility cordage during their missions.

Over the decades since, the usefulness of paracord has become so evident, that it is now a must-have tool in one’s backpack - and would eventually shape military operations in the field. Paracord has become so popular that is it now used not only by the military, but also by veterans, outdoor enthusiasts, and even NASA engineers and astronauts!

Paracord’s usefulness is limited only by your imagination, but some of the most common uses include equipment harnessing, guy lines, household repair, everyday carry, hammock and tent suspension, and the list goes on and on. Today, anyone who loves the outdoors, also knows what paracord is and how its versatility can help save the day in most any situation.

There are six primary types of military paracord (AKA MIL-C-5040-H parachute cordage), and then there are multiple types of newer, or non-military recognized parachute cords (i.e. MIL-SPEC, MIL-STYLE, SurvivorCord®, etc.), all of which vary in strength, function, and even quality.

The strength of paracord can vary from 95 to 1,000+ pounds, which is one of the primary reasons paracord is the most trusted cordage ever. The primary types of paracord used around the world include: Type I, Type IA, Type II, Type IIA, Type III, Type IV, MIL-SPEC, MIL-STYLE, Commercial-Spec, and our own patented SurvivorCord® series.

| Paracord Type |

Minimum Tensile Strength |

Maximum Stretch |

Core Strands |

Sheath Strands |

| I | 95 LBS (43 KG) | 30% | 1 | 16 |

| IA | 100 LBS (45 KG) | 30% | NONE | 16 |

| II | 400 LBS (181 KG) | 30% | 4 - 7 | 32 or 36 |

| IIA | 225 LBS (102 KG) | 30% | NONE | 32 or 36 |

| III | 550 LBS (249 KG) | 30% | 7 - 9 | 32 or 36 |

| IV | 750 LBS (340 KG) | 30% | 11 | 32 or 36 or 44 |

| SurvivorCord® | 620 LBS (281 KG) | 15% | 10 | 36 |

| SurvivorCord® XT | 1,026 LBS (465 KG) | 15% | 14 | 44 |

MILITARY Paracords

MIL-C-5040-H PARACORD

MIL-C-5040-H (MILITARY SPECIFICATION: CORD, FIBROUS, NYLON) is the official military specification referring to a set of products that fall under it, and it spells out in exhaustive detail all the minimum requirements that a parachute cord needs to meet government functional requirements.

The required specifications include requirements for color, product diameter, strand material, number of internal and external strands, denier of each strand, number of strands per braid, manufacturer identification markers, how the cordage is prepared (pre-shrinkage, UV resistance, mold resistance, etc.), its packaging, shipping requirements, and so much more. If a product does not meet these requirements, it cannot be called MIL-C-5040-H paracord.

The “H” at the end of the specification refers to the latest version of the requirements, and according to the U.S. Government, "H" is now inactive for new design and is no longer used except for replacement purposes – as of October 1st, 1997.

TYPE I PARACORD

Type I paracord has a breaking strength of 95 pounds, should measure 950 feet per pound of cordage, and has a 30% stretch. This type of parachute cord has the smallest diameter because it only has 1 core strand inside the outer sheath, has 16 strands in the outer sheath, and it is one of the cheapest paracords to make because it doesn’t require a lot of material to manufacture. Subsequently, it also doesn’t hold much weight. Because it is so lightweight, it is usually one of the best paracord choices for crafting small, decorative paracord projects like zipper pulls.

TYPE IA PARACORD

Type IA paracord has a breaking strength of 100 pounds, should measure 1,050 feet per pound of cordage, and has a 30% stretch. This type of parachute cord is like Type I cordage, but it doesn’t have an inner core and instead uses a stronger type of nylon thread for the 16 sheath or mantle strands. This type of parachute cord is also used for smaller, decorative paracord projects like keychains due to its low weight capacity.

TYPE II PARACORD

Type II paracord, usually used in projects like lanyards or keychains, has a tensile breaking strength of 400 pounds, should measure 265 feet per pound of cordage, and has a 30% stretch. To achieve this higher tensile strength, this cordage has 4 - 7 inner nylon strands in the core, and 32 or 36 nylon strands in the mantle. Type II parachute cord is the type of military cordage that many commercial paracords emulate. Visually, it looks like it has the same external dimensions as standard 550 paracords, but functionally is nowhere near as strong or useful.

TYPE IIA PARACORD

Type IIA paracord is just Type II paracord with its inner core removed. It has a breaking strength of 225 pounds, should measure 495 feet per pound of cordage, and has a 30% stretch requirement. It must have 32 or 36 strands in the sheath, and like Type I and Type IA paracords, paracord projects like bracelets or lanyards are typically made with this type of parachute cord.

TYPE III PARACORD

Type III paracord, also known as “550 Cord” by most military veterans, has a minimum breaking strength of 550 pounds, should measure 225 feet per pound of cordage, and and has a 30% elongation spec. When most people refer to paracord, this is what they are talking about. This is the utility cordage used in the suspension lines of parachutes, and as such is the most used type of paracord in any of its forms: MIL-C-5040-H, MIL-SPEC, MIL-STYLE, or Commercial paracords.

550 paracord must have between 7 and 9 nylon strands in its core, and either 32 or 36 nylon strands in its mantle. Most popular paracord projects are made with this type of parachute cord, which is why it is the most used paracord out there – for survival, utility, and aesthetics.

TYPE IV PARACORD

Type IV paracord (aka 750 cord) is like Type III parachute cord, but it was designed to be MUCH stronger and is typically found in the parachute harnesses used to drop heavy vehicles and supplies from logistics aircraft. If you’ve ever seen a picture or video of a tank being dropped from a military airplane, it is more than likely attached to the parachute canopy with many of these Type IV paracord stands.

750 Cord has a breaking strength of 750 pounds (it all becomes obvious now!), should measure 165 feet per pound of cordage and has a 30% stretch. This cord is very strong, with 11 inner nylon core strands, and either 32, 36, or 41 nylon strands in the sheath.

Because of its increased resource requirements to manufacture, Type 4 paracord can be very pricey. While it is some of the strongest paracord out there, its increased diameter makes paracord projects, knots, and other uses a bit more challenging.

NON-MILITARY PARCORDS

MIL-SPEC PARACORD

MIL-SPEC (short for “Military Specification”) is an unofficial term for MIL-C-5040-H parachute cord and is not officially recognized by the U.S. government. It is mostly a marketing term, used by both authentic vendors using the term unknowingly, or by unscrupulous vendors who are trying to convince their customers that their product meets a government specification, without naming that specification.

“MIL-SPEC parachute cord” usually refers to a product visually or functionally similar to either TYPE III or TYPE IV paracords, but again...this is not an official designation with official specifications, so it can really mean whatever the vendor or distributor thinks it means.

MIL-STYLE PARACORD

MIL-STYLE is a term used by more and more U.S. manufacturers that refers to paracords that meets or exceeds MIL-C-5040-H requirements. Since the official specification is no longer updated, newer paracords that meet the requirements of MIL-C-5040 paracord, but maybe come in newer colors outside of the original allowed spec (only Off-White and Olive-Drab are in the MIL-C-5040 specification), these would be called MIL-STYLE.

Other examples of MIL-STYLE paracord include our patented SurvivorCord® and SurvivorCord® XT paracords, which utilize baseline MIL-C-5040-H paracord specifications, but then we add our life-saving survival strands to the core. So normally, MIL-STYLE = MIL-C-5040-H + more color options and advanced features. This is a term that tries to incorporate all the original U.S. government quality standards, and at the same time honestly differentiate itself from the official spec.

COMMERCIAL-SPEC PARACORD

Commercial-Spec paracord is very similar if not functionally the same as MIL-SPEC parachute cord. It is a term that refers to paracord types (Type I, Type 2, Type 3, etc.), but these paracords do not meet the minimum requirements for the MIL-C-5040-H specification. This means that the quality of commercial paracord is much lower than real military cordage. There is no minimum requirement for construction, pre-shrinkage, UV or Mold resistance, etc.

This term is not publicly used as often as it was in the past, due to the valued reputation of MIL-C-5040 or MIL-STYLE paracords, and the term has in many cases been largely replaced with the term MIL-SPEC – again, a marketing term. In the end though, the terms are interchangeable and basically mean the same thing – No promises!

Many parachute cord crafters and artists will use Commercial-Spec paracord for their products and creations when they want the visual aesthetics of paracord, but do not require the strength and durability (and therefore manufacturing costs) associated with military parachute cords.

SURVIVAL PARCORDS

ORIGINAL SURVIVORCORD®

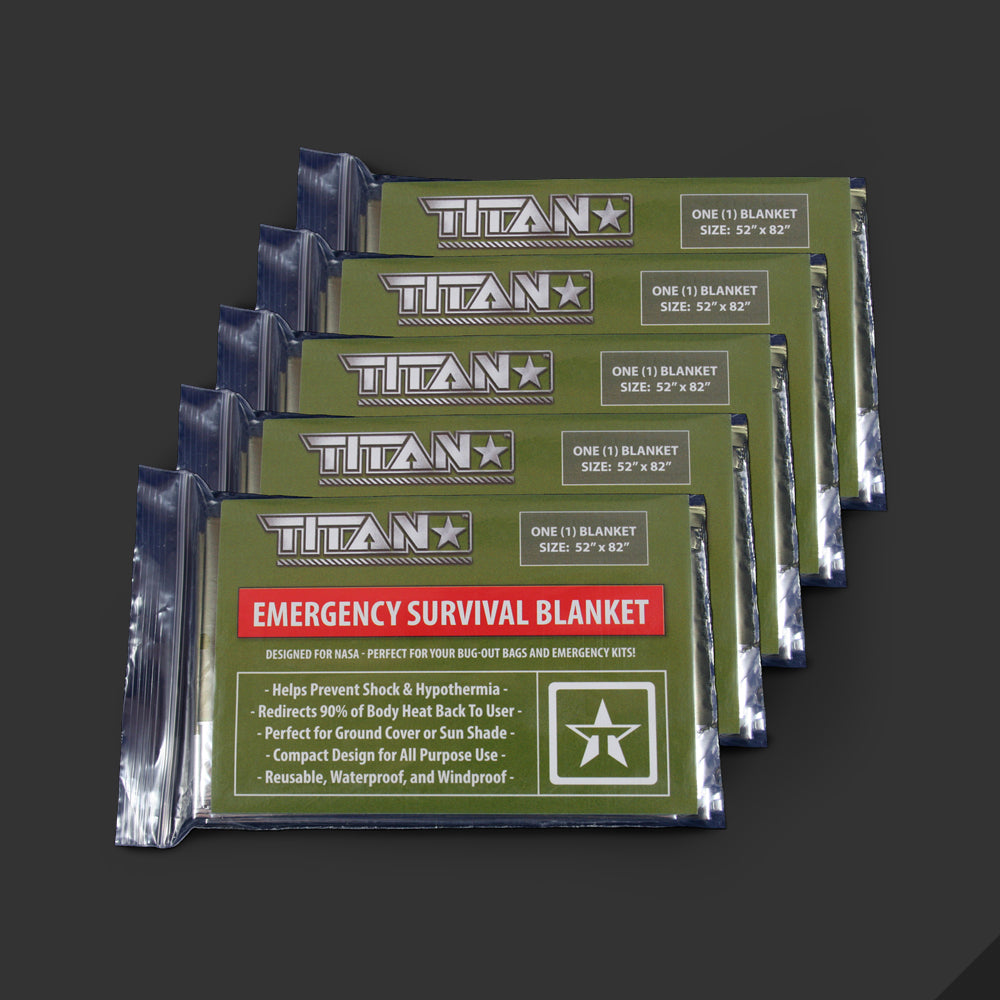

SurvivorCord® is our original, patented version of our own MIL-STYLE survival paracord. Invented in 2012 by the founder of TITAN Survival (Jarod King), and officially patented in 2015, SurvivorCord® was created by merging MIL-C-5040-H Type III paracord with the concept of an internal mini-survival kit that could be used in an emergency.

Originally developed for battlefield use in Afghanistan, it is the original “survival paracord”, or “survival cord” when misspelled, and is one of the most popular paracord brands in the world. Our original SurvivorCord® looks and performs just like normal military-grade Type III 550 paracord from the outside, and exceeds MIL-C-5040-H specifications for 550 cord in general, but the inner core has 3 extra potentially life-saving survival strands added:

- 25 LB Mono-Filament Fishing Line

- 30 AWG Brass Multi-Purpose Utility Wire

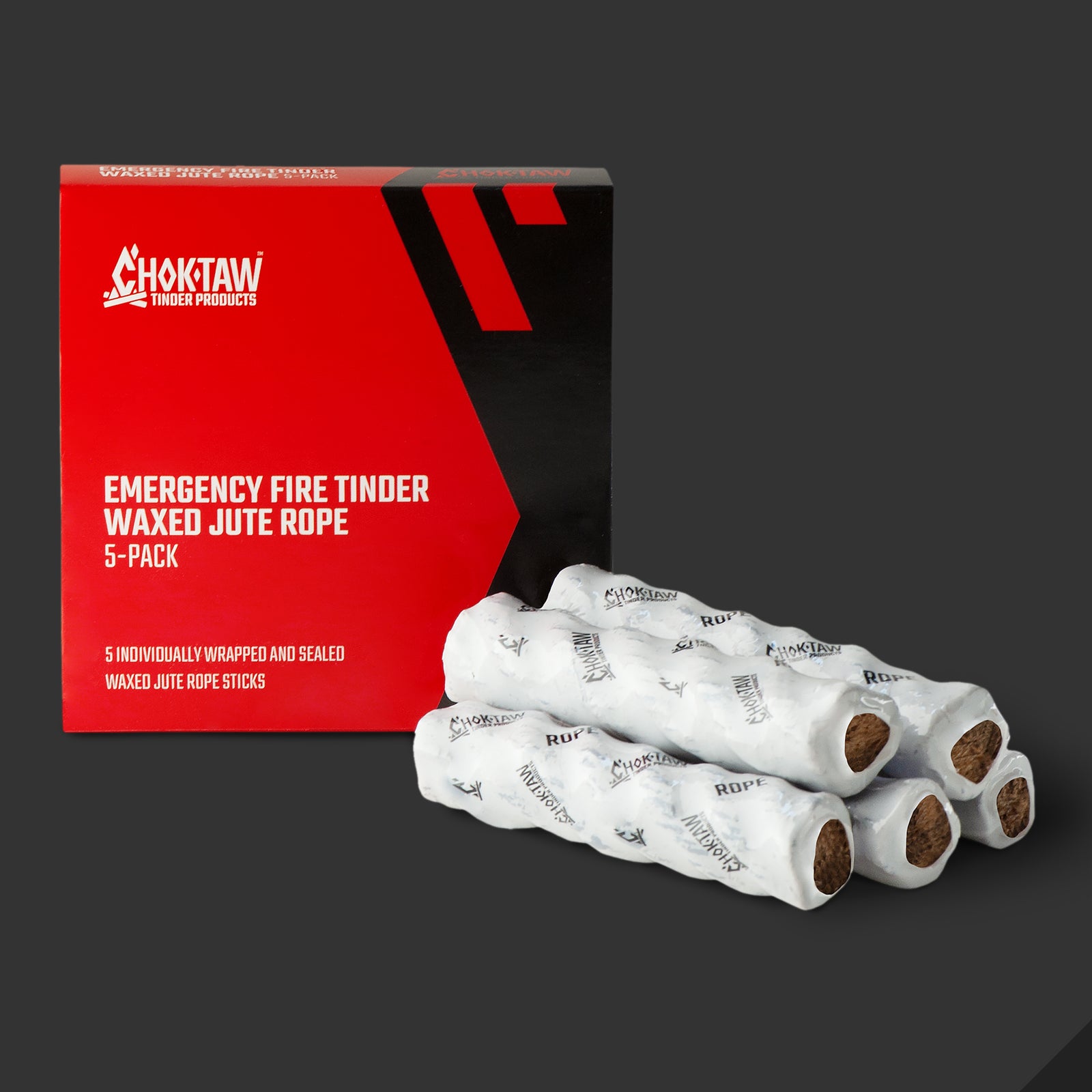

- Proprietary Waterproof Waxed Jute Tinder

Not only do these additional strands come in handy in an unforeseen emergency, but the added strands increase the Tensile Strength of the cord to 620 LBS.

SURVIVORCORD® XT

Our newer SurvivorCord® XT is similar to the original SurvivorCord®, but it is based off of MIL-C-5040-H Type IV 750 Cord, and we modified the cores survival strands to cater more towards Bushcraft and Survivalist functions, rather than battlefield uses. As such, the Tensile Strength comes in at 1,026 LBS on average, and the 3 internal core survival strands are:

- 25 LB Braided Fishing Line

- 110 LB Multi-Purpose Kevlar Strand

- Proprietary Waterproof Waxed Jute Tinder

SurvivorCord® comes in more than 22 unique color variations, and our cordage is trusted and used by veterans, survivalists, and outdoor enthusiasts all over the world.

SURVIVORCORD® IS PROTECTED BY U.S. PATENTS: 9,528,204 and 9,926,652.

Leave a comment (all fields required)